Results 1 to 7 of 7

Thread: 737 pedestal Trim Gauge

-

08-19-2008, 10:01 AM #1

737 pedestal Trim Gauge

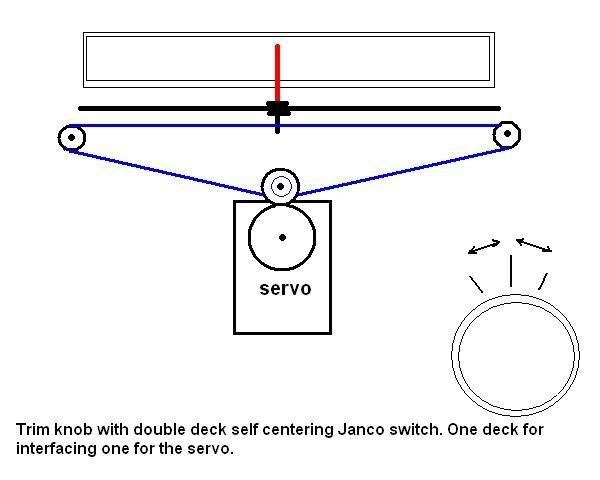

One idea to make it work as it should since the knob is supposed to return to neutral.

AC motor in the real plane, spring loaded self centering rotary here.

The pointer will move in both directions as slow as the gearing ratio allows.

One contact turns the sevo clockwise

One contact turns it countercl.

Jackpilot

Jackpilot

B737-700 Posky

FS9/P.Magenta

without PMSystem

-

08-19-2008, 11:18 AM #2

Comments/ improvements allowed

Jackpilot

B737-700 Posky

FS9/P.Magenta

without PMSystem

-

08-21-2008, 04:27 AM #3150+ Forum Groupie

- Join Date

- Jun 2008

- Location

- Stafford, UK

- Posts

- 161

That is a good idea. (I didnt know the knob returned to the centre).

How do you make sure that the trim indication doesnt move out of sync with the simulator?

Tom.

-

10-04-2008, 10:48 AM #475+ Posting Member

- Join Date

- Jan 2007

- Location

- Spain

- Posts

- 146

Check out the news on www.cpflight.com

cheers

Peter

-

11-24-2008, 06:56 AM #5

good question i would like to know that too

regards john d

-

11-24-2008, 11:18 AM #6

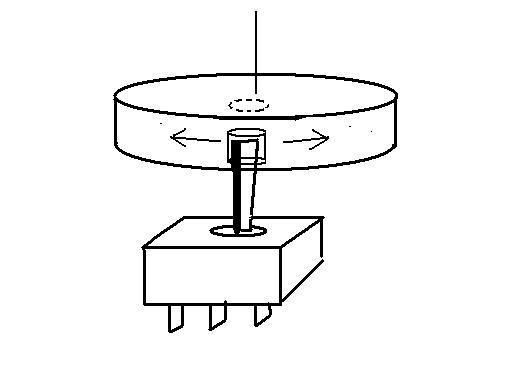

It stays in Sync because the Trim Knob rotary has two decks and commands both the servo AND a temporary contact to the sim (joystick button assigned or interface card) for "rudd trim right" or "rudd trim left"

The deviation of the pointer is calibrated through the gearing choice.

Cost (except panel) $20ish.

I was lucky enough to get the appropriate Rotary (Janco double decker) on EBay But a regular rotary could be converted with a tab in the shaft held in neutral by two strong springs

Could work too with the Trim Knob linked this way to a DTDP (on) off (on) paddle switch toggle.(dual pole dual throw, momentary /off /momentary)

Sorry about the crude drawing!Jackpilot

B737-700 Posky

FS9/P.Magenta

without PMSystem

-

11-24-2008, 12:12 PM #7150+ Forum Groupie

- Join Date

- Jun 2008

- Location

- Stafford, UK

- Posts

- 161

Thats going to be very difficult to get right and still doesnt solve all the sync issues.

You would have to know how many trim commands a second your interface will pick up and then select a gearing ratio to make sure the pointer moves that many trim positions a second. If the trim commands accelerate when you hold it deflected for a set time then you will also need to accelerate the servo after that many commands.

If you turn off your sim or the computer resets trim to 0 it is out of sync and cannot be put back in sync using the knob as it will send futher commands to the sim.

What I would do is get hold of a servo interface card to control the servo from your PC and use the knob to send commands to the pc. That way they are always in sync regardless of computer resets, game loads, game losses and trim command acceleration.

Similar Threads

-

737 Pedestal

By 737NG Builder in forum Where to Start Building a Home CockpitReplies: 19Last Post: 08-26-2009, 01:53 PM -

RAL colour CDU pedestal/radio pedestal

By curtis in forum General Builder Questions All Aircraft TypesReplies: 2Last Post: 01-07-2009, 05:03 PM -

737 Pedestal

By Upwego in forum General Builder Questions All Aircraft TypesReplies: 0Last Post: 12-05-2007, 01:49 PM -

ISI & Analog TRim Gauge

By Rodney Stagner in forum PM General Q & AReplies: 1Last Post: 01-27-2006, 10:41 PM -

Moving the flap indicator e trim gauge

By null null in forum PM General Q & AReplies: 1Last Post: 11-13-2004, 10:58 PM

Reply With Quote

Reply With Quote

Explore Exciting Connections for a Night of Fun in Your City

Ready for an Unforgettable Night?...