Results 1 to 1 of 1

-

03-13-2009, 11:28 AM #1

Scratchbuilding for the Simulator

Scratchbuilding for the Simulator

Since the explosion of the sim building hobby several years ago, there has been an unending quest for parts to enable the most emmersive experience outside of a professional Level-D simulator.

Many parts can be found through various vendors, both electronic and building related. Sometimes though, there is nothing that is quite right, is too expensive, or just isn't available for the type of simulator you are building or plan to build.

This is where scratchbuilding begins. This article is an overview of what can be accomplished with a bit of mechanical, electronic, and creative ingenuity.

Most of us building a simulator don't have multiple degrees in the disciplines required for engineering an entire cockpit, but that's not needed either. Instead, thinking through a problem, or problems while envisioning a solution and assessing and using the skills you do have can take you far.

Members of this community have scratchbuilt everything from an entire shell all the way down to the smallest replica Duzs fastener and nearly everything in-between. A lot of it takes a firm commitment to see the project through no matter how many obsticles there are to overcome. If one solution isn't working as planned, then try another. Think about how the final product will look or operate and what you will have to use for material and engineering to achive that.

Shell construction can be as simple as a plywood box of the approximate dimensions and proportions for a light GA aircraft all the way up to a shell that uses ribs and stringers from wood or metal to nearly the exact dimensions of a real airliner nose section. Plans can be found in the download area for the more popular aircraft represented by our builders.

Panel creation is another area where just about everyone has their own methods of construction and backlighting. Panels can be as elaborate or as simple as your skills and budget allow. Many make theirs on a CNC machine with the fine engraving found on panels produced by Specra-Lux for Boeing and Airbus. Others are simply a layered print from a desktop inkjet printer with the appropriate holes cut for switches and indicators glued to a plastic backing plate of the correct size for the panel. Backlighting has been done with embedded LED's and incandescent bulbs, as well as just one big lamp behind a whole panel such as an overhead. Some have also used 1:1 training posters for their aircraft glued to a backing sheet with the holes cut for various switches and indicators.

"How do these crazy people come up with these ideas" you ask?

That's a good question.

In all honesty there is no simple answer. Some study the actual part if they have access and try to replicate that part with easily obtainable material and some ingenuity. Others try to approximate the look of the part, but replicate it's function nearly as the real part would operate. The old saying "Neccesity is the Mother of Invention" should be the motto of this hobby. A lot of attempts to build a part for the simulator don't always work out the first, and sometimes the second try. In a case like this, another approach and re-thinking of the problem is usually the bet bet. Sometimes even taking a break for a few days or a week can give a fresh look to the problem and a new solution to try.

Programming, though not a physical building task, can be thought of as scratchbuilding too. Some interface programs have to be written to make the equipment you've scratchbuilt work in the sim. Just like the physical building aspects of this hobby, not everyone has the skills for this aspect of scratchbuilding, but there are other ways. FSUIPC is a great drag & drop interface that works well for most equipment integrated into the sim, but can't replicate system logic, which is what most programming involves. There is also cockpit software available for more popular aircraft that takes the worry out of this part of the scratchbuilding process. In some cases it will also take a lot of money out of your wallet at the same time. Some payware flight models also include the system logic which can be read by FSUIPC. Most however, do not output this information where FSUIPC can access it.

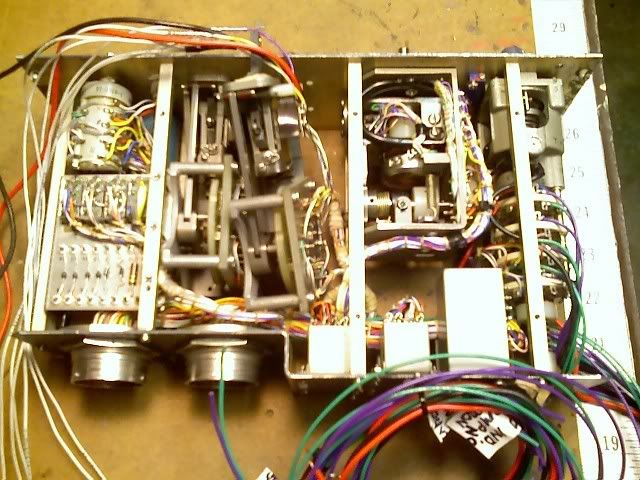

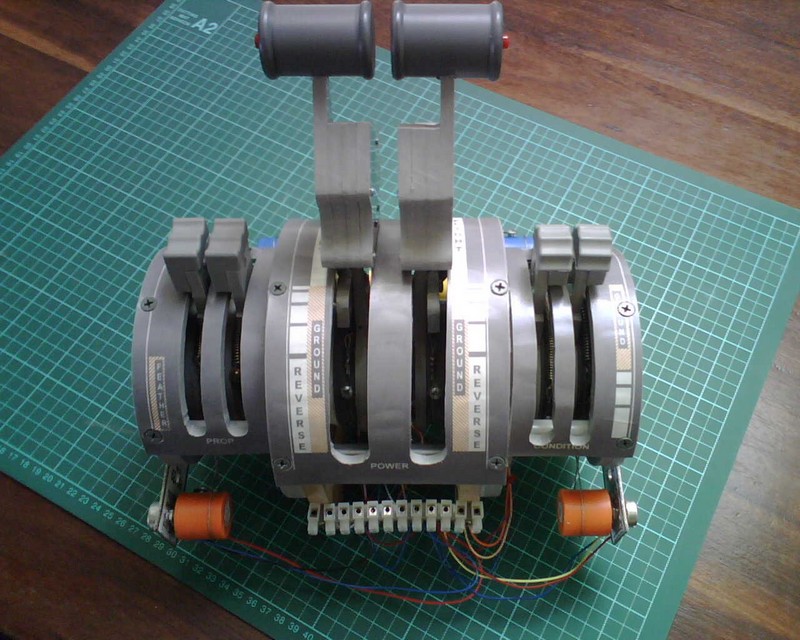

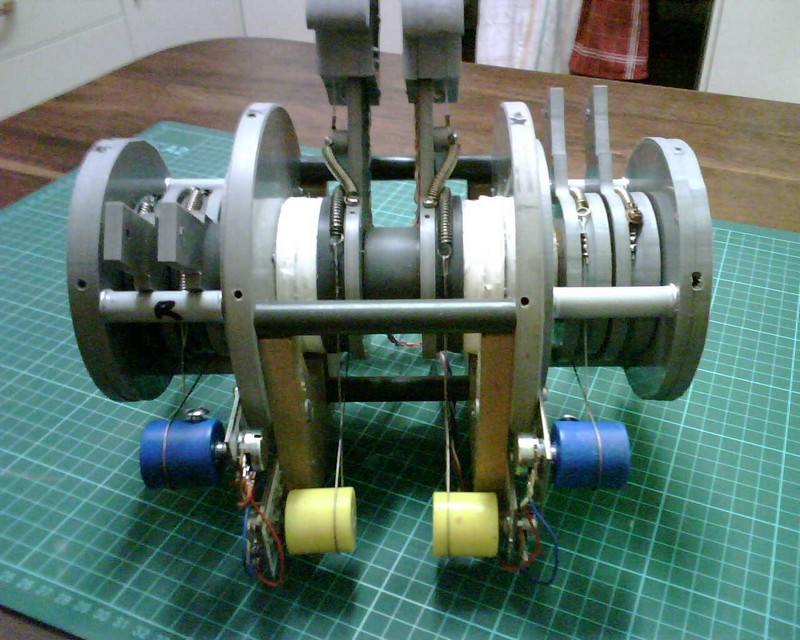

Equipment modification of actual aircraft components is an electrical or electronic scratchbuilding part of the hobby. There are companies within the hobby that can do this for you for a steep price, or with a little study can be accomplished by the builder. If the component is thought of as just another box with switches and indicators it can be treated in much the same way as a wholly sctachbuilt panel. Though the wiring may be a little more involved, it is not impossible to reverse engineer and interface most electro-mechanical aircraft equipment into a simulator. The problem some run into though is not understanding how the equipment worked as designed. Most of this equipment sent out a signal to another piece of equipment and sometimes to a second before routing the signal back to the box in question. Most of this has to be bypassed as our sims are not wired like the real aircraft and those other components are usually missing. The rear jack(s) on this equipment is where most of the headaches start. It's usually best to go right to the switches and indicators within the box and leave the jacks to the real aircraft techs.

Most builders using this method are left out in the cold by mainstream manufacturers of equipment for more popular aircraft. Aircraft equipment from leading & trailing edge position indicators, to actual aircraft instruments, to throttle quadrants and everything in between have been modified and integrated into home built simulators. Many of these parts are cheap to purchase, many are not. Your budget will determine what is feasable to modify and what to totally scratchbuild yourself.

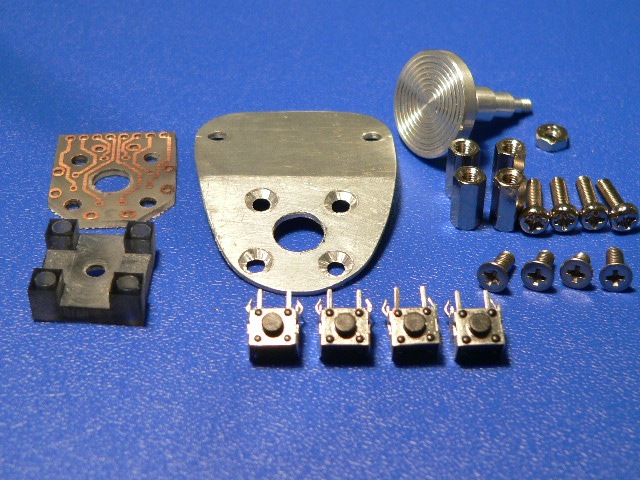

Materials and supplies used for scratchbuilding are as varied as the sims we build. Aluminum is the prefered choice for those that have the neccesary tools and skills to use it. Wood is a friendlier and cheaper material that can also give excellent results if prepared properly for final finishing. Plastic or acrylic is also widely used for panel building. And why not? That's what the original equipment manufacturers use. Both aluminum and wood can be used for structual building and the main instrument panel. Many members of the site have used wood that you can't tell from aluminum after proper finishing. Using aluminum for simpler projects with only hand tools and a couple of smaller power hand tools is not out of reach for most with a modestly equipped shop.

Instrument bezels, panel backing plates, throttle shafts, control linkage parts, and a number of other parts and pieces can easily be made with a couple of small power tools and a hand file. You don't need a $5000 lathe and a mill to turn out acceptable parts for your simulator.

For those electrically inclined, there are several major electronic supply houses in the States and several in the UK and Europe. Rotary encoders, passive parts, and LED's as well as supplies can be purchased, usually very cheaply. So cheaply in fact, that many times the shipping is more than the parts ordered. Just roll that into the cost of building your simulator. There's not many ways around that unless you visit the store in person for will-call pick up. e-Bay is another option and many here have regular electronics suppliers that are reliable and offer fast service at a reasonable shipping fee.

To sum up the above, when it comes to scratchbuilding for your simulator, you are only limited by your imagination. Even without a background or experience in the above catagories, it's not impossible to achieve what might at first seem impossible. There are many here at the site that have the experience and background to help you along, and will help you if you ask.

After all, that's why we're members here.

Thanks to all the members here for the photos of their scratchbuilt projects. There were many more I would like to have included, but were not found on the server.

Take Care.

Michael E. Carter

Boeing Skunk Works

Boeing Skunk Works

Remember...140, 250, and REALLY FAST!

We don't need no stinkin' ETOPS!

Powered by FS9 & BOEING

Similar Threads

-

Another MUST SEE!!! (Simulator)

By Jake 747 400 in forum Welcome to MyCockpit New here? Introduce Yourself!Replies: 3Last Post: 10-04-2009, 07:12 AM -

DC-10 simulator

By samson in forum My Cockpit UpdateReplies: 4Last Post: 06-15-2009, 02:41 PM -

Scratchbuilding for the Simulator

By Michael Carter in forum MyCockpit News and AnnouncementsReplies: 8Last Post: 04-18-2009, 07:36 AM -

F-16 SIMULATOR!

By dodiano in forum General Builder Questions All Aircraft TypesReplies: 11Last Post: 02-21-2007, 11:20 AM -

My 737-700 Simulator

By Rafael Castaņeda in forum PM General Q & AReplies: 0Last Post: 01-16-2006, 11:01 PM

Reply With Quote

Reply With Quote

Search Prettys Womans from your city for night

5.Sharing an Essay about PIC16F877